The needed temperature for the curing or drying process is ensured with gas burner, oil burner or electrical insets. In case of gas heating we can manufacture oven with direct or indirect heating. Depending on design and technology, there are oven with A or U form, block construction or drying tanks, but according to the customer requirements we can build any kind of design. Depending on design the parts are delivered into the ovens by means of hoists or conveyor systems. The plant is more effective because of thick isolation, separated door movements, air curtains and heat recovery system.

Task of the water dryer is the drying of the part surface after the pre-treatment process. The parts are delivered by means of hoists or chain track into the plant, where the parts will be dried by high air speed. The heating and design of the dryer can be by means of gas, electricity or oil. The treating temperature of the dryer is lower, than the temperature of the oven. The structure of the plant (panel elements) has at least 3 layers and mineral wool isolation with 120 kg/m3 consistence. The structure is made with panel connection protection, so we can minimise heat loss.

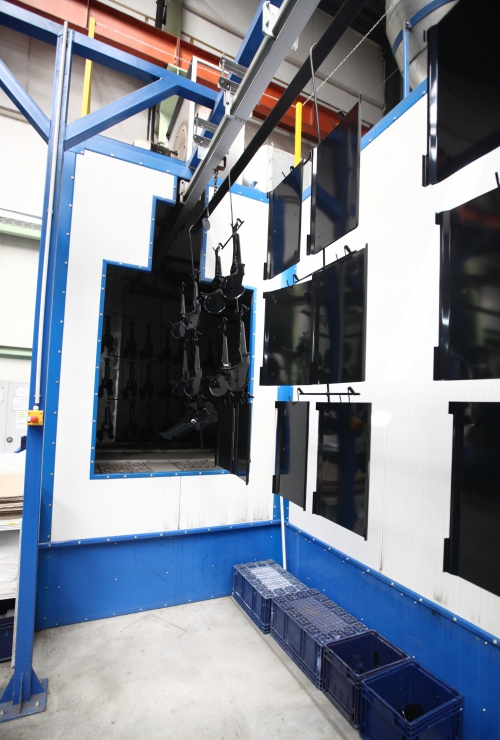

Task of the KTL curing oven is the curing of KTL paint on the part surface. The curing oven is built from sandwich panels, internal holding frame, air heater unit, internal and external air technology. Depending on design they have doors or air curtain. The inner air circulating of the KTL curing oven is more intensive, than the circulating of the powder curing oven. The oven has an airproof structure to have minimal heat loss during the operation. The KTL curing oven can have continuous or tact operation. A diagram can be made about every single curing. The controlling can happen with relays (at smaller, simpler oven) or with PLC. In case of PLC controlling we ensure remote supervision. The structure of the plant (panel elements) has at least 3 layers and mineral wool isolation with 120 kg/m3 consistence. The structure is made with panel connection protection, so we can minimise heat loss.

In case of the more energy effective function of our powder curing oven we fit the continuous system with entry and exit air curtain and systems with tact operation with doors. Depending on the hall features we can reach the most economical operation with the A-oven. The oven can be completed with a “jelly”-zone. The structure of the plant (panel elements) has at least 3 layers and mineral wool isolation with 120 kg/m3 consistence. The structure is made with panel connection protection, so we can minimise heat loss.

Task of this plant is to increase the drying speed of the painted parts. The construction depends on the technological demands. In case of the more energy effective function of the plant we fit the continuous system with entry and exit air curtain and systems with tact operation with doors. The structure of the plant (panel elements) has min. 3 layers and mineral wool isolation with 120 kg/m3 consistence. The structure is made with panel connection protection, so we can minimise heat loss.

Task is heat treatment and controlling of the materials. Usually they have electrical heating and tiristor controlling. The cycles - heating-up, keeping-warm, cooling-down – can be adjusted to the split of a second. The temperatures can differ from the adjusted values minimally. The structure of the plant (panel elements) has at least 3 layers and mineral wool isolation with 120 kg/m3 consistence. The structure is made with panel connection protection, so we can minimise heat loss.

Task is the cooling of parts for the needed temperature of the next technological step. The next technological process after the cooling is usually the downloading of parts or painting or powder coating after the water drying. With the installation of the cooling units we can speed up the technological process and increase the capacity. The function of the cooling units is based on the cooling with cold air with high air speed.

As additional unit for the manual material moving system we recommend the curing oven with cross tracks, manual trolley or drag unit and manual doors. The manual curing oven is built from sandwich panels, internal holding frame, air heater unit, internal and external air technology. The structure of the plant (panel elements) has at least 3 layers and mineral wool isolation with 120 kg/m3 consistence. The structure is made with panel connection protection, so we can minimise heat loss.

We deliver our after burner plants (TNV) mainly with heat recovery function.