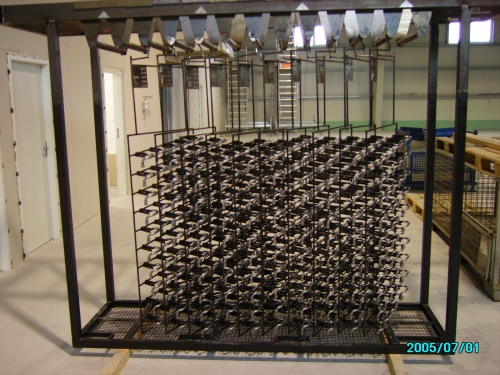

The material moving systems ensure the safe and cost efficient transport of the parts along the painting line. The material moving system builds a connection between the technological positions, so the whole painting line builds a complete unit. Our plants are individually planned, the manufacturing happens on our location in Bonyhád. We support our customers with individual hook and rack constructions.

Parts can be delivered with this unit fast and safe between the technological points. They have small place requirement and moderately high load capacity. One of the most important advantages is that during the transport the parts don’t take place on the floor.

We ensure between the treating zones and working stations the needed logistic system, floor conveyor, lifting and turning units for the effective and intelligent material moving. The biggest advantage is that the parts with high dimensions and weight don’t have to be lifted high from the floor.

This is a unit for the fast and safe delivery of heavy and big parts between the technological points.

An important task is the effective space using during the surface treatment.